Microwave Technology Can Be Used to Measure Moisture Content of Ores, Coal and Other Minerals

Microwave technology is used in two ways for measuring moisture content of various types of ores, coal and other minerals:

-

By reflection or resonance

-

Transmission

The technology “by reflection” means that the microwave is emitted into the material bed and the analysis is made on the microwave frequency that is reflected from the material to be measured. The technology is limited to measuring the free or surface moisture of the material. Although some believe that bound moisture is also measured, this is only true for materials with a very low attenuation factor such as grain. Attenuation is a general term that refers to any reduction in the strength of a signal. The reflection technique fails to be a reliable bulk moisture determination for material with a high attenuation since it causes the measured microwaves to only penetrate a thin surface layer of the material. This is especially important for materials such as magnetite where penetration will be at best of the order of a centimeter.

The resonance frequency of the microwave field is detuned and dampened depending on the water content of the material. The changes in the microwave frequency are measured by the receiver antenna and this signal is then evaluated by the microprocessor based control unit. With the measurement of the above parameters and their evaluation, it is possible to determine moisture content and material density separately.

How the technology works

Microwave moisture analyzers work on the principle that water has a very higher dielectric constant compared to most other materials.

When microwaves interact with water molecules within the material they slow down (and hence change phase) and weaken (attenuate) as the energy is transferred to the water.

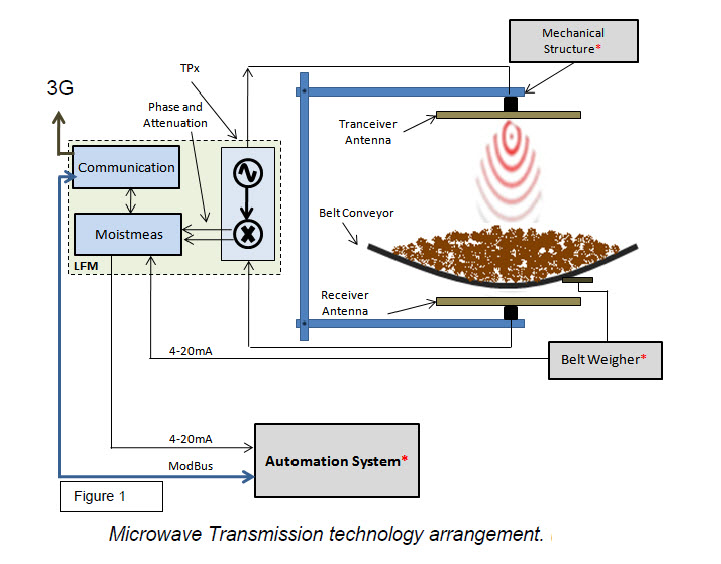

A low profile antenna transmits a beam through the material on the conveyor belt. The signal is received by a receiver antenna located below the conveyor belt. The received signal is compared to the transmitted signal for phase and amplitude change. See figure below.

Both the change in phase shift and attenuation is measured and processed by the control unit to calculate the moisture content of the material measured.

Since phase shift and attenuation is dependant and influenced by the amount of material to be measured (% moisture by weight), a measurement of the mass loading on the belt is required to compensate or “normalise” the microwave measurements. The mass, profile or height measurement is provided by use of belt weighers, radar level, ultrasonic level, radar scanners etc, or even a combination of these devices. In some cases the density of the material is measured using a Nuclear Type Density Transmitter.

Another technology that is used for online moisture measurement is NIR (Near Infra Red) which is limited in the fact that it only measures surface moisture and does not penetrate the whole burden of material. In Dust Extinction Moisture (DEM) applications where the moisture is measured immediately following sprayers, the moisture reading will be biased to read high moisture which is true for the surface but not for the whole burden of material.

And that’s a burden that a mining company need not bear.

0 comment